Our cases

AI Forecasting for spare parts demand

Problem

For companies managing engineering systems, a key challenge lies in ensuring the right spare parts and consumables are available when needed. Items such as filters, pumps, and valves are critical to uninterrupted operations, yet demand for them is often irregular. Overstocking ties up capital, while shortages lead to costly delays and downtime. Our partner, Nero Group LLC, faced these issues and needed a more accurate way to forecast demand in order to optimize stock planning and improve service reliability.

Result

With demand forecasting in place, Nero Group LLC significantly improved the efficiency of its inventory planning. Stock levels became more balanced, delays caused by missing parts were minimized, and working capital was used more effectively. This not only increased operational reliability but also strengthened the company’s reputation with its customers by ensuring timely service and uninterrupted support. The solution proved scalable, setting the foundation for continued optimization as the company grows.

How did we achieve it?

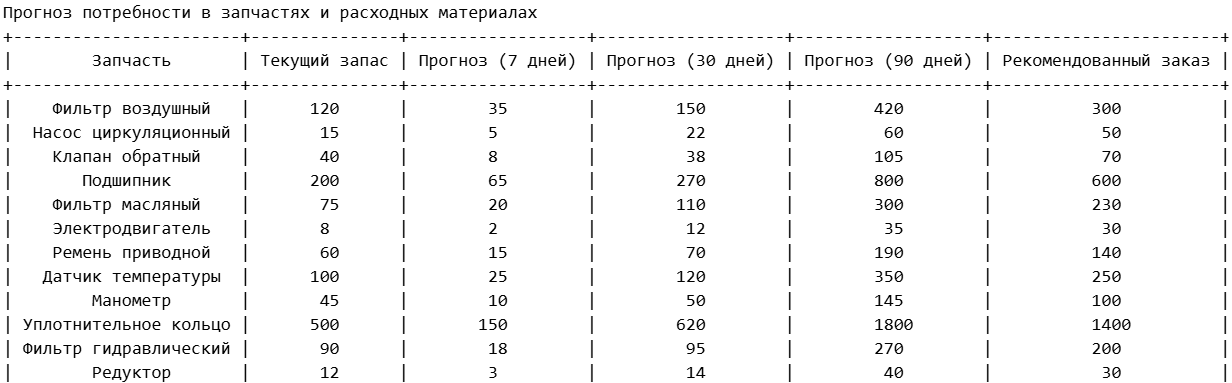

We developed an AI-driven forecasting system that analyzes historical consumption patterns and operational data to predict future demand for spare parts and consumables. To ensure smooth integration with existing processes, we built an internal API that automatically receives operational data from the company’s systems. For each piece of equipment, the API applies machine-learning recalculated parameters that were later multiplied by dynamically updated with real-world input such as runtime hours, usage intensity, sensor readings and etc. to determine when specific parts are likely to require replacement. The solution provided Nero Group with clear insights into which items would be required, in what quantities, and at what times.

Impressed?

We can build something

just as powerfull for you

Tell us what you're looking to achieve and we'll suggest

the most effective solution tailored to your timeline and budget.

Or contact us by email, phone or through social media:

Or contact us by email, phone or through social media:

Or contact us by email, phone or through social media: